Services

Information of Quality Visual Inspection Standard

The Quality Visual Inspection Standard for window film application, as outlined by the International Window Film Association, includes the following key guidelines:

-

Scope of Inspection: Inspection applies only to the installed film and not inherent defects in the glass itself.

-

Adhesion and Cure Time: Installed films require a curing period due to residual water between the film and glass after installation. This "adhesive cure time" can vary depending on film thickness, metallic coatings, and climatic conditions. Visual inspections may occur before full adhesion is achieved, but effects during cure (such as bubbles and haze) should not be considered defects.

-

Visual Inspection Criteria:

-

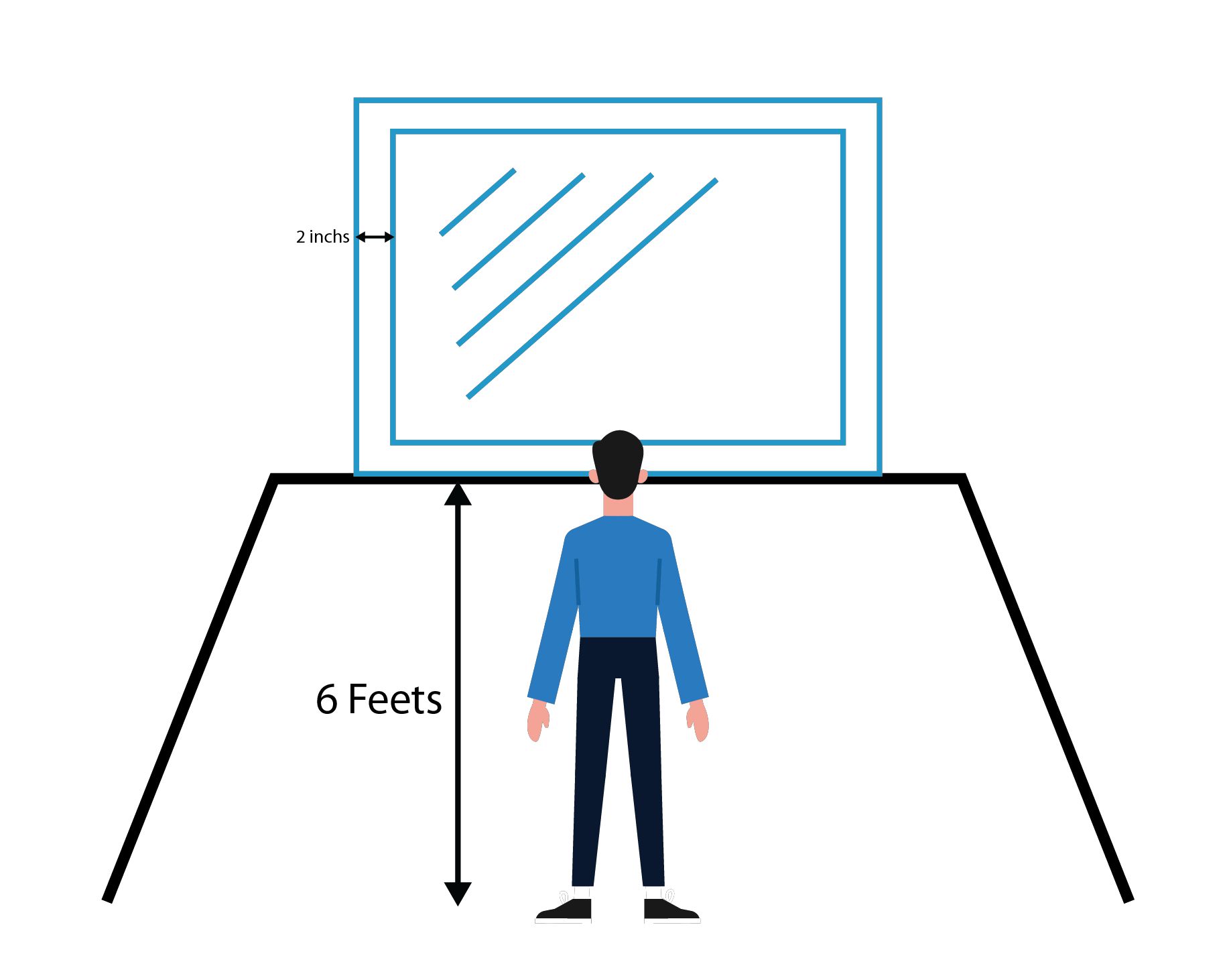

The film should be viewed at a right angle from the room side, at a distance of at least 6 feet (2 meters), in natural daylight (not direct sunlight).

-

The inspection should focus on the main visual area, excluding a 2-inch (50mm) wide perimeter band.

-

-

Acceptance Criteria: The installation is deemed acceptable if the following are unobtrusive (effects during cure should be disregarded):

-

Dirt particles

-

Hair and fibers

-

Adhesive gels

-

Fingerprints

-

Air bubbles

-

Water haze

-

Scores and scratches

-

Film distortion

-

Creases

-

Edge lift

-

Nicks and tears

-

-

Perimeter Band: A 2-inch (50mm) wide perimeter band should be assessed similarly, with a small number of particles acceptable in areas with poor frame conditions.

-

Edge Gaps: Edge gaps typically range from 1/32 to 1/16 inch (1-4mm) to allow for water removal during installation. This ensures the edges are not raised due to contact with the frame, which could cause peeling.

-

Thicker Safety Films: For thicker safety films, edge gaps can range from 1/32 to 1/8 inch (1-5mm) for films of 7 mil (175). Combination solar control safety films also follow this standard.

-

Edge Gap Recommendations: For darker films (e.g., tinted or metallized), an edge gap of up to 1/16 inch (2mm) is recommended to minimize light lines around the film's edge.

-

Film Splicing: For large glass panels, film splicing is necessary. The splice line should be straight and parallel to the frame margin, with a maximum gap of 1/64 inch (1mm). Overlapping or butt-jointing the films is acceptable.

-

Special Coatings: Films with special high-performance coatings may have longer cure times. Consult the manufacturer for specific curing details.

These standards ensure that the window film installation meets quality expectations while accounting for natural variations during the curing process.